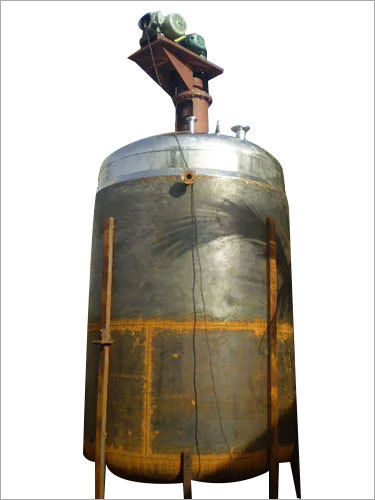

SS Nutsche Filter

SS Nutsche Filter Specification

- Cleaning Method

- CIP (Clean In Place), Manual

- Connecting Type

- Flanged/Jacketed/Nozzle

- Temperature Range

- -10C to +150C

- Filter Type

- Pressure Nutsche Filter

- Media Type

- Liquid/Solid Separation

- Capacity

- 10 Litre 10,000 Litre

- Pressure

- Full Vacuum to 6 Bar

- Efficiency (%)

- Up to 99%

- Flow Rate

- 20 5000 LPH (Depending on Model/Size)

- Condition

- New

- Material

- Stainless Steel (SS 304/316)

- Mesh

- SS Perforated Plate With Suitable Mesh Support

- Diameter

- Customizable (typically 300 mm 2000 mm)

- Construction

- Vertical, Cylindrical Vessel with Agitator and Filter Plate

- Medium Filter

- SS Sintered/Cloth/Perforated Mesh

- Weight

- Varies as per Capacity (Approx. 150 kg 2000 kg)

- Shape

- Cylindrical

- Feature

- Corrosion Resistant, Leak-Proof Design, Easy Operation, Durable Build

- Mounting Type

- Leg Mounted/ Skid Mounted

- Automation Grade

- Semi-Automatic or Automatic

- Agitator

- Manual or Motorized, Top Mounted

- Power Requirement

- 0.5 5 HP (for Motorized Models)

- Application

- Pharmaceuticals, Chemicals, Dyes, Food Processing

- Sealing

- PTFE Gasket/ O-Ring

- Jacket

- Available for Heating/Cooling

- Inspection Port

- Provided for Visual Checking

- Design Standard

- ASME/ DIN/ Customized

- Surface Finish

- Internal Mirror Polished, External Matt Finish

- Discharge

- Bottom Discharge with Valve/Flush Bottom

- Operating Mode

- Batch

- Vessel Thickness

- 4 mm 18 mm

- Lid Type

- Removable or Hydraulic Lift

SS Nutsche Filter Trade Information

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 7 Days

About SS Nutsche Filter

Our company is a reputed business entity, actively involved in presenting a world-class SS Nutsche Filter to innumerable respected clients. This type of filter is the best suitable to be utilized for handling flammable, toxic, corrosive and odor-noxious materials. It is designed with effective filtration system, which allows simple filtration of liquid. The SS Nutsche Filter is made of top of the line stainless steel with progressive casting and welding technology to ensure its high resistance to chemical reaction & corrosion formation, impact resistance and longer performance.

Key Features and Construction

This pressure Nutsche filter incorporates a vertical cylindrical vessel with an agitator and filter plate, designed to deliver up to 99% filtration efficiency. Provided with SS perforated plates and suitable mesh supports, its diameters are customizable from 300 mm to 2000 mm. The vessel supports capacities from 10 to 10,000 litres, and is capable of handling full vacuum to 6 bar pressure, as well as temperature ranges between -10C and +150C.

Advanced Operating Modes and Safety

Available in both semi-automatic and automatic grades, the SS Nutsche Filter ensures easy operation and reliable performance. Its mounting optionsleg or skid mountedoffer flexibility of installation, while the removable or hydraulic lift lid, PTFE gasket/O-ring sealing, and integrated inspection port enable safe and efficient handling during processing and visual inspection.

Versatile Applications and Customization

Ideally suited for liquid-solid separation in pharmaceuticals, chemicals, dyes, and food processing industries, this filter system accommodates varying flow rates from 20 to 5000 LPH. The filtration grade meets industrial standards using SS sintered, cloth or perforated mesh, and can be customized in terms of vessel size, design standard, and automation level to match specific operational needs.

FAQs of SS Nutsche Filter:

Q: How is the SS Nutsche Filter with Agitator typically used in industrial processes?

A: This filter is employed for batch liquid-solid separation in industries such as pharmaceuticals, chemicals, dyes, and food processing, effectively filtering slurries and facilitating washing and drying within a single vessel.Q: What are the advantages of a mirror-polished internal surface and matt external finish?

A: Mirror-polished internal surfaces promote hygienic processing and easy cleaning, while the matt external finish offers a premium look and reduces fingerprint marks, making maintenance simpler.Q: When should I opt for manual versus motorized agitator models?

A: Manual agitator models are suitable for smaller scales or processes requiring variable agitation, whereas motorized options offer consistent mixing for larger batches and improved efficiency, especially when handling viscous or heavy materials.Q: Where can this filter be installed and what mounting options are available?

A: The SS Nutsche Filter fits in production and pilot plants; installation is flexible with leg-mounted or skid-mounted options depending on space and operational requirements.Q: What is the process for cleaning the SS Nutsche Filter?

A: Cleaning is performed either manually or using a CIP (Clean In Place) system, ensuring efficient removal of residues and maintaining sterile conditions, especially important for pharmaceutical and food applications.Q: What benefits does the heating/cooling jacket provide during operation?

A: The jacket enables temperature control of the process media, supporting both heating and cooling cycles, which is essential for reactions or filtration requiring specific thermal conditions to optimize yield or prevent degradation.Q: How is leak-proof performance and corrosion resistance achieved in this system?

A: The vessel is constructed from high-grade stainless steel (SS 304/316) and sealed using PTFE gaskets or O-rings, ensuring robust corrosion resistance and leak-proof operation even under pressure and vacuum conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

DHANANJAI EQUIPMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |