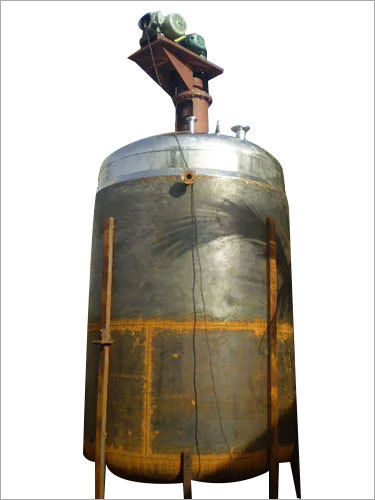

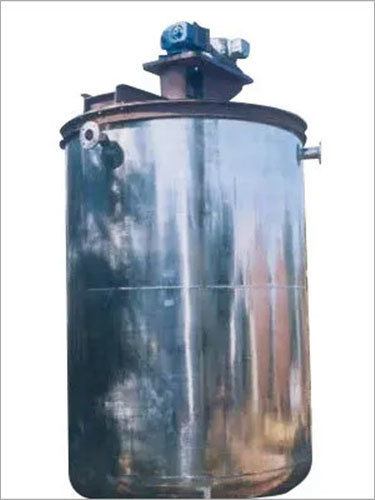

Aerofoil Agitator Tank

Aerofoil Agitator Tank Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 7 Days

About Aerofoil Agitator Tank

The Aerofoil Agitator Tank that brought by us is designed for making mixing of liquids and chemicals together easier. Such tank is widely installed and used in pharmaceutical, cosmetic, chemical, and food industries due to its high leakage proof design, high impact & abrasion resistance, low maintenance cost, rust proof surface finish and long life. Moreover, the Aerofoil Agitator Tank can be availed in a lot of capacities, dimensions and diameters as per requirement of its application.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Agitator Tank Category

|

DHANANJAI EQUIPMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |