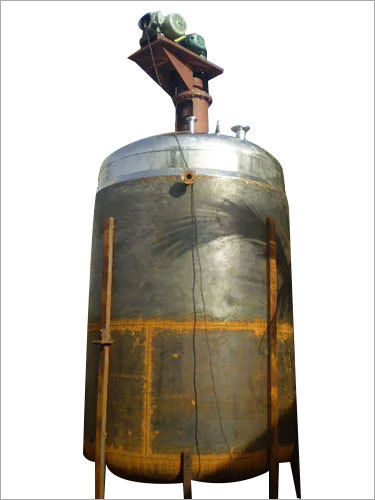

Gum Mixing Chemical Reactor

Gum Mixing Chemical Reactor Specification

- Product Type

- Gum Mixing Chemical Reactor

- General Use

- Industrial gum and adhesive mixing and reaction processes

- Material

- Stainless Steel (SS304/SS316)

- Capacity

- 500 Liters to 10,000 Liters (customizable)

- Weight (kg)

- Approx. 2000 - 8000 kg (depending on capacity)

- Computerized

- No

- Automatic

- Yes

- PLC Control

- Available (Optional)

- Mixer Type

- Agitator with Scraper

- Heating System

- Jacketed (Steam/Electric/Oil Heating)

- Shaft

- Single/Double Shaft (customizable)

- Drive Type

- Electric Motor Drive with Gearbox

- Voltage

- 380/415 Volt, 3 Phase, 50/60 Hz

- Motor

- 3 HP to 15 HP (customizable by size)

- Dimension (L*W*H)

- Variable as per capacity (e.g., 3000mm x 1800mm x 2700mm for 5000L)

- Packaging Material

- Export Standard Packing (Wooden/Plastic wrap)

- Feature

- High-precision mixing, corrosion resistance, leak-proof design, easy cleaning

- Color

- Silver (Polished Stainless Steel)

- Pressure Rating

- Atmospheric to 6 bar (customizable)

- Application Industries

- Adhesive, Rubber, Chemical, Paint, Food, Pharmaceutical

- Exterior Finish

- Matte/Polished Stainless Steel

- Sealing Method

- Mechanical Seal/Gland Packing

- Control Panel

- Digital/PLC Based (Optional)

- Service Support

- On-site installation & commissioning, after-sales support

- Discharge Type

- Bottom Discharge with Valve (Manual/Pneumatic)

- Interior Finish

- Mirror Polished for CIP (Clean-In-Place) applications

- Temperature Range

- Up to 200°C (depending on process requirements)

- Agitator Speed

- 20-120 RPM (Variable Speed Drive if required)

- Insulation

- Provided (Glass Wool/PU Foam as per requirement)

Gum Mixing Chemical Reactor Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 7 Days

About Gum Mixing Chemical Reactor

Customizable Features for Diverse Applications

This reactor is engineered to meet a wide range of process requirements. Pressure and temperature settings, as well as agitator speed and insulation type, can be tailored to specific production needs. The mirror-polished interior ensures hygienic conditions for food and pharma, while the exterior can be finished in matte or polished stainless steel, enhancing durability and ease of maintenance.

Reliable Service and Support Network

Our reactors come with comprehensive service including on-site installation, commissioning, and after-sales support. Both dealers and manufacturers in India provide prompt assistance, ensuring minimal downtime and seamless integration into existing operations. Packaging meets export standards, guaranteeing safe transport and delivery.

Superior Materials and Leak-Proof Design

Constructed from robust SS304/SS316 stainless steel, the reactor is built for high corrosion resistance and leak-proof performance. The heating system is jacketed for steam, electric, or oil heating, with single or double shaft customizable options. This high-precision mixing solution improves product consistency and reduces contamination risks.

FAQs of Gum Mixing Chemical Reactor:

Q: How is the agitator speed controlled in the Gum Mixing Chemical Reactor?

A: The reactor features a variable speed drive for the agitator, allowing users to adjust speed between 20-120 RPM according to process requirements. This ensures optimal mixing of different gum and adhesive formulations.Q: What sealing methods are available for leak-proof operation?

A: Depending on process needs, the reactor can be equipped with either a mechanical seal or gland packing, providing robust leakage protection during high-pressure and high-temperature operations.Q: When should the mirror-polished interior finish be selected?

A: A mirror-polished interior is recommended for applications requiring Clean-In-Place (CIP) capabilities, such as food or pharmaceutical industries, where hygiene and easy cleaning are critical.Q: Where is this reactor typically installed and used?

A: The Gum Mixing Chemical Reactor is widely used across manufacturing plants in adhesives, rubber, chemicals, paints, food processing, and pharmaceuticalsprimarily installed in industrial setups in India and exported globally.Q: What is the process for heating within the reactor?

A: The reactor is jacketed and supports steam, electric, or oil heating systems. The choice of heating medium depends on process temperature requirements and operational preferences.Q: How does the bottom discharge system benefit usage?

A: The bottom discharge equipped with manual or pneumatic valves enables efficient product removal, reduces residue and cleaning time, and improves overall workflow in batch processing.Q: What benefits do customers gain from onsite installation and after-sales support?

A: Customers receive professional installation and commissioning services, along with reliable after-sales technical support, minimizing downtime and ensuring optimum reactor performance throughout its service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Reactor Category

SS GMP Reactor

Price 50000.00 INR / Piece

Minimum Order Quantity : 2 Units

Voltage : 220V / 380V / 415V (Custom as per requirement)

Product Type : SS GMP Reactor

Material : Other, Stainless Steel (SS 304/316/316L)

Automatic : Other, SemiAutomatic / Automatic (Optional)

Limpet Coil Reactor

Price 50000.00 INR / Piece

Minimum Order Quantity : 4 Pieces

Voltage : 220V / 380V / 440V

Product Type : Limpet Coil Reactor

Material : Other, Stainless Steel (SS304/SS316)

Automatic : Other, SemiAutomatic or Manual

Pressure Vessel

Price 85000.00 INR / Piece

Minimum Order Quantity : 4

Voltage : 220440 V

Product Type : Pressure Vessel

Material : Stainless Steel

Automatic : No

SS Lab Reactor Vessel

Price 75000.00 INR / Piece

Minimum Order Quantity : 4

Voltage : 220240 V

Product Type : Lab Reactor Vessel

Material : Other, Stainless Steel (SS 304/316)

Automatic : Other, SemiAutomatic

|

DHANANJAI EQUIPMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |