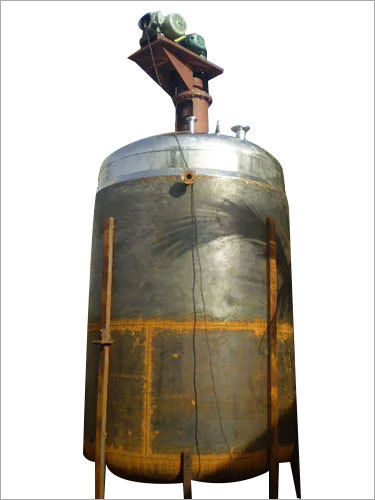

Pressure Vessel

Pressure Vessel Specification

- Product Type

- Pressure Vessel

- General Use

- Industrial Liquid Storage, Mixing, Chemical Processing

- Material

- Stainless Steel

- Capacity

- 1000 Liters

- Weight (kg)

- 240 kg

- Computerized

- No

- Automatic

- No

- PLC Control

- Optional

- Mixer Type

- Agitator

- Heating System

- Steam Jacket or Electric Heater (Customizable)

- Shaft

- Single Shaft

- Drive Type

- Motor Driven

- Voltage

- 220-440 V

- Motor

- 2 HP Electric Motor

- Dimension (L*W*H)

- 2200 mm x 900 mm x 1200 mm

- Packaging Material

- Wooden Box

- Feature

- Leakproof, High Corrosion Resistance, Robust Design

- Color

- Metallic Silver

- Application Area

- Chemical, Pharmaceutical, Food Processing, Water Treatment

- Pressure Gauge

- Provided

- Nozzle Configuration

- Multiple Inlet & Outlet Nozzles

- Manhole

- Provided (Top/Side positioned)

- Temperature Range

- -20°C to 150°C

- Design Standard

- ASME Section VIII Div. 1

- Thickness

- 6 mm (Shell) / 8 mm (Dished Ends)

- Mounting Type

- Leg Mounted

- Insulation

- Available (Optional)

- Gasket Type

- EPDM/Silicon/PTFE

- Orientation

- Vertical

- Tested By

- Hydraulic Pressure Test

- Working Pressure

- Up to 10 Bar (Customizable)

- Surface Finish

- Mirror or Matt Finish Available

Pressure Vessel Trade Information

- Supply Ability

- 10 Per Day

- Delivery Time

- 7 Days

About Pressure Vessel

ThePressure vessel that we put forward is engineered to be utilized separation of two or more components as per their relative boiling point. Such column contains innumerable elements and the functionality of the said elements is totally depend on boiling temperature of fluid substances. In addition, thePressure vesselis made of first-rate stainless steel at state of the art machining facility that ensure its super performance, corrosion resistance, low maintenance and longer performance.

Engineered for Stringent Industrial Applications

With its robust stainless steel construction and adherence to ASME Section VIII Div. 1, this pressure vessel is built for demanding environments in chemical, pharmaceutical, food processing, and water treatment sectors. Its high corrosion resistance and leakproof design make it exceptionally reliable for storing or mixing valuable liquids.

Why Choose Customizable Features?

Customization means you can select the ideal working pressure (up to 10 Bar), heating system (steam jacket or electric), nozzle configurations, surface finish, and insulation based on your plant requirements. These options offer flexible solutions to fit unique process needs while optimizing operational efficiency.

Safety and Quality Assurance

Every vessel undergoes a thorough hydraulic pressure test to ensure integrity and safety. The inclusion of quality gaskets (EPDM/Silicon/PTFE), a robust manhole, and a pressure gauge ensures peace of mind during high-pressure, variable-temperature operations.

FAQs of Pressure Vessel:

Q: How is the pressure vessel tested to ensure safety and durability?

A: The vessel undergoes a rigorous hydraulic pressure test as per ASME Section VIII Div. 1 standards to confirm its leakproof performance and structural integrity under the designated working pressure.Q: What materials are used in construction and why are they beneficial?

A: Manufactured from stainless steel, the vessel offers excellent resistance to corrosion, ensuring a longer lifespan and suitability for handling chemicals, pharmaceuticals, and food-grade substances.Q: Where can this pressure vessel be installed, and for which applications is it most suitable?

A: It is ideal for installation in chemical plants, pharmaceutical facilities, food processing units, and water treatment stations, serving purposes such as liquid storage, mixing, and chemical processing.Q: What makes the vessels design robust and reliable for industrial usage?

A: Key factors include its vertical orientation, 6 mm thick shell/8 mm thick dished ends, multiple nozzle options, and motor-driven agitator, all ensuring consistent performance, structural stability, and versatile process adaptation.Q: How does the heating system work, and can it be customized?

A: The vessel supports either a steam jacket or electric heater, allowing you to select the most effective heating method for your process. This customization ensures optimal temperature control within the -20C to 150C range.Q: What advantages does the optional insulation provide?

A: Optional insulation helps maintain desired temperature stability, reduces heat loss, and improves energy efficiencyparticularly important for thermal processes in chemical and food applications.Q: When should the EPDM, Silicon, or PTFE gaskets be selected?

A: The choice depends on process media and temperature requirements. Use EPDM for water-based solutions, Silicon for high thermal stability, and PTFE for compatibility with aggressive or corrosive chemicals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Reactor Category

SS GMP Reactor

Price 50000.00 INR / Piece

Minimum Order Quantity : 2 Units

Product Type : SS GMP Reactor

Color : Other, Mirror / Matt Finish (Natural Steel)

Computerized : No

Drive Type : Other, Top Mounted Gearbox with Motor

Gum Mixing Chemical Reactor

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Gum Mixing Chemical Reactor

Color : Other, Silver (Polished Stainless Steel)

Computerized : No

Drive Type : Other, Electric Motor Drive with Gearbox

Limpet Coil Reactor

Price 50000.00 INR / Piece

Minimum Order Quantity : 4 Pieces

Product Type : Limpet Coil Reactor

Color : Other, Metallic Silver

Computerized : No

Drive Type : Other, Motor Driven

SS Lab Reactor Vessel

Price 75000.00 INR / Piece

Minimum Order Quantity : 4

Product Type : Lab Reactor Vessel

Color : Other, Silver

Computerized : No

Drive Type : Other, Motor Driven

|

DHANANJAI EQUIPMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |