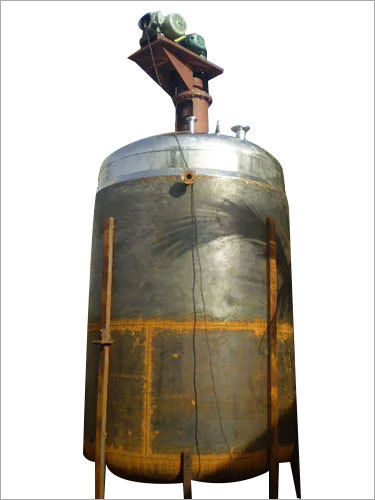

SS Distillation Column

SS Distillation Column Specification

- Product Type

- Distillation Column

- General Use

- Industrial distillation and separation processes

- Material

- Stainless Steel (SS)

- Capacity

- Custom/As per requirement

- Weight (kg)

- Varies with design (Typically 500-5000 kg)

- Computerized

- No

- Automatic

- Yes

- PLC Control

- Optional/Available as per request

- Mixer Type

- Agitator Optional

- Heating System

- Steam or Electric Jacketed

- Shaft

- Stainless Steel

- Drive Type

- Motor Driven

- Voltage

- 220V/380V/415V (As Required)

- Motor

- Heavy Duty Electric Motor

- Dimension (L*W*H)

- Custom/As per specification

- Packaging Material

- Standard Export Packing/Wooden or Bubble Wrap

- Feature

- Corrosion Resistant, High Efficiency, Easy Maintenance

- Color

- Metallic Silver

- Application

- Used in chemical, pharmaceutical, petrochemical industries

- Number of Trays/Stages

- Customizable

- Sealing Type

- Gasket or Welded Construction

- Working Pressure

- Designed for Atmospheric or Mild Pressure Operation

- Maintenance

- Low maintenance, easy to dismantle and clean

- Surface Treatment

- Mirror or Matt Finish

- Installation Type

- Vertical Free-standing on Skid or Foundation

- Temperature Range

- Upto 250°C (Depending on application)

- Internal Components

- SS Structured Packing/Bubble Cap/Valve Trays

- Feed/Discharge Size

- As per project design

- Manufacturer Warranty

- 12 Months Against Manufacturing Defects

- Insulation

- Provided (if required)

SS Distillation Column Trade Information

- Supply Ability

- 10 Per Day

- Delivery Time

- 10 - 60 Days

About SS Distillation Column

Assisted by experienced and dedicated professionals, we are committed towards proposing our esteemed patrons with the best-in-grade SS Distillation Column. This is ideally suitable to be used for a lot of applications as per needed fluid capacity hold up and decline in pressure. The column has many elements and their functionality absolutely depends on heating temperature of fluid components. Moreover, the SS Distillation Column is fabricated at our ultra-advanced facility using graded stainless steel and components that guarantees outstanding performance, robust construction and longer shelf life.

Custom-Built for Industrial Separation

The SS Distillation Columns modular design allows for customization in capacity, tray count, and internal components to align with diverse industrial distillation requirements. Whether your project demands bubble cap trays or structured packing, these options are tailored during fabrication, ensuring optimal performance in separation and purification processes for various industries.

Robust Design and Low Maintenance

Constructed from corrosion-resistant stainless steel and available in either mirror or matt finish, this distillation column guarantees durability in harsh environments. The easy-to-dismantle and clean architecture, combined with optional insulation and high-grade gasket or welded sealing, minimizes operational downtime and maintenance effort, keeping your process running efficiently.

Flexible Installation and Operation

The column is designed for vertical, free-standing installation, either on a skid or directly on a foundation. Country-specific voltage options and heavy-duty motors make integration seamless, while features such as automatic operation and programmable controls (PLC) provide process flexibility. Steam or electric heating jackets accommodate a wide range of applications.

FAQs of SS Distillation Column:

Q: How is the SS Distillation Column installed and what are the available options?

A: The column is designed for vertical, free-standing installation and can be mounted either on a skid or directly on a foundation. Installation type depends on your facilitys layout and project requirements.Q: What benefits does the mirror or matt surface treatment provide for the SS Distillation Column?

A: Mirror finish enhances cleanability and reduces product adhesion, which is ideal for sanitary environments, while matt finish offers increased durability against scratches. Both types ensure corrosion resistance and maintain the integrity of the stainless steel construction.Q: What range of pressures and temperatures can the column handle safely?

A: The SS Distillation Column is designed for atmospheric or mild pressure conditions and operates safely at temperatures up to 250C, depending on specific application and project design.Q: Which industries typically use this type of distillation column?

A: This distillation column is widely used in chemical, pharmaceutical, and petrochemical industries for industrial-scale distillation and separation processes, due to its customizable features and robust construction.Q: How are the trays or stages in the column tailored to project needs?

A: The number and type of trays or stagessuch as bubble cap, valve trays, or structured packingare fully customizable. They are configured according to process requirements to maximize separation efficiency for each application.Q: What internal components and control options are available?

A: You can select between stainless steel structured packing, bubble cap trays, or valve trays as internal components. Automation is standard, with optional PLC control for advanced process monitoring and adjustment. An agitator and heating system (steam or electric) can also be provided as required.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

DHANANJAI EQUIPMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |