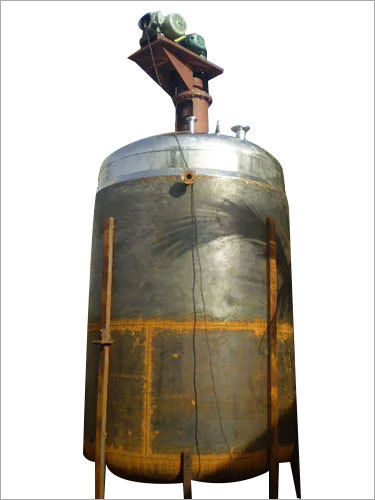

SS Lab Reactor

SS Lab Reactor Specification

- Product Type

- SS Lab Reactor

- General Use

- Chemical, Pharmaceutical, Food & Lab Research

- Material

- Stainless Steel (SS 304/316)

- Capacity

- 1 Liter to 100 Liters

- Weight (kg)

- Approx. 50 kg to 250 kg

- Computerized

- Optional

- Automatic

- Semi-Automatic / Automatic

- PLC Control

- Available (Optional)

- Mixer Type

- Anchor / Propeller / Turbine

- Heating System

- Electric / Steam Jacket

- Shaft

- SS Shaft with mechanical seal

- Drive Type

- V-Belt / Gear Box Driven

- Voltage

- 220V/380V/415V

- Motor

- 0.5 HP to 5 HP

- Dimension (L*W*H)

- As per model (e.g., 800*600*1200 mm)

- Packaging Material

- Wooden/Carton

- Feature

- Leak Proof, Rust Resistant, High Mixing Efficiency, Easy to Clean

- Color

- Silver

- Power Source

- Electric / Steam

- Sealing Type

- Mechanical Seal / Gland Packing

- External Finish

- Matt / Mirror Polished

- Safety Features

- Pressure Relief Valve, Temperature Controller, Emergency Vent

- Vessel Thickness

- 3 mm to 8 mm (depending on size and pressure)

- Viewing Glass

- Available (Borosilicate Glass) for Observation

- Operating Temperature

- Up to 200°C

- Nozzle Configuration

- Multiple Inlets/Outlets, Sampling, Vent, Charging, Thermowell etc.

- Operating Pressure

- Atmospheric to 6 bar

- Utility Connections

- Included for Steam, Water and Chilled Water Circulation

- Mounting

- Floor Mounted / Skid Mounted

- Internal Finish

- Mirror Polished (<0.5 Ra micron)

- Application

- Chemical, Pharmaceutical, Food, Cosmetics and Research Applications

SS Lab Reactor Trade Information

- Supply Ability

- 10 Per Day

- Delivery Time

- 7 Days

About SS Lab Reactor

SS Lab Reactor we present is ideal for a variety of chemicals heating / cooling application. It is designed with high-end induction electrical motor which helps speed up the chemical production rate with high efficiency. Such reactor is ideal to be utilized in industry of pharmaceuticals, chemical, food, coating, resin, paint, printing ink, etc. Made of graded stainless steel with advanced casting technique, the SS Lab Reactor is easy to install & maintain, and comes in many models, sizes and specifications.

Engineered for Safe and Reliable Operation

Every SS Lab Reactor is equipped with advanced safety mechanisms including a pressure relief valve, emergency vent, and temperature controller. Its robust construction, using high-grade stainless steel and mirror-polished surfaces, reduces contamination risks and ensures the vessel withstands rigorous laboratory or industrial usage without corrosion or leakage.

Precision Mixing and Process Flexibility

Designed with a choice of anchor, propeller, or turbine mixers and powered by motors from 0.5 HP to 5 HP, the reactor delivers high mixing efficiency. Various drive types, including V-belt and gearbox options, accommodate a range of viscosities. The inclusion of multiple inlets/outlets and a borosilicate viewing glass enables real-time observation and flexible process control.

User-Friendly Design and Easy Maintenance

The mirror-polished internal finish provides a smooth, easy-to-clean surface, while external finishes are available in matt or mirror. Floor or skid-mounted models suit different space requirements, and all units are shipped in secure wooden or carton packaging. Optional computerized and PLC control features further enhance usability and precision.

FAQs of SS Lab Reactor:

Q: How do I choose the correct vessel thickness for my application with the SS Lab Reactor?

A: The vessel thickness, ranging from 3 mm to 8 mm, depends on the size and operating pressure required in your process. Thicker vessels are ideal for higher pressure applications, up to 6 bar. Our team can assist in selecting the appropriate specification based on your material and process needs.Q: What is the cleaning process for the SS Lab Reactors mirror-polished interior?

A: The internal mirror finish (under 0.5 Ra micron) provides a highly smooth surface, minimizing residue adherence. Cleaning is straightforwardoften requiring only mild detergent, water rinse, and, if necessary, standard CIP (Clean-in-Place) procedures suitable for lab and industrial use.Q: When should I opt for a mechanical seal versus a gland packing sealing type?

A: A mechanical seal is recommended for processes involving higher pressures or volatile substances, ensuring superior leak prevention. Gland packing may be suitable for lower-pressure applications or when budget constraints exist. The choice depends on operational demands and safety expectations.Q: Where can I observe the process inside the reactor during operation?

A: Each reactor is fitted with a borosilicate viewing glass designed for high visibility and chemical resistance, allowing safe observation of mixing and reaction progress in real time without interrupting reactor operation.Q: What are the main benefits of computerized or PLC control in the SS Lab Reactor?

A: Optional computerized or PLC control allows automation of critical parameters such as temperature, mixing speed, and process timing. This enhances repeatability, data recording, and safety while reducing manual intervention, making your process more efficient and controlled.Q: How does the SS Lab Reactor handle utility connections for thermal management?

A: The reactor is equipped with dedicated utility connections for steam, water, and chilled water circulation, supporting both electric and steam-jacket heating. This enables precise temperature control throughout a wide operational range up to 200C.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Reactor Category

SS GMP Reactor

Price 50000.00 INR / Piece

Minimum Order Quantity : 2 Units

Computerized : No

Mixer Type : Other, Anchor / Propeller / Paddle / Turbine (Custom as per process)

Product Type : SS GMP Reactor

Drive Type : Other, Top Mounted Gearbox with Motor

Limpet Coil Reactor

Price 50000.00 INR / Piece

Minimum Order Quantity : 4 Pieces

Computerized : No

Mixer Type : Agitator

Product Type : Limpet Coil Reactor

Drive Type : Other, Motor Driven

Gum Mixing Chemical Reactor

Price 50000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Mixer Type : Other, Agitator with Scraper

Product Type : Gum Mixing Chemical Reactor

Drive Type : Other, Electric Motor Drive with Gearbox

Pressure Vessel

Price 85000.00 INR / Piece

Minimum Order Quantity : 4

Computerized : No

Mixer Type : Agitator

Product Type : Pressure Vessel

Drive Type : Other, Motor Driven

|

DHANANJAI EQUIPMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |