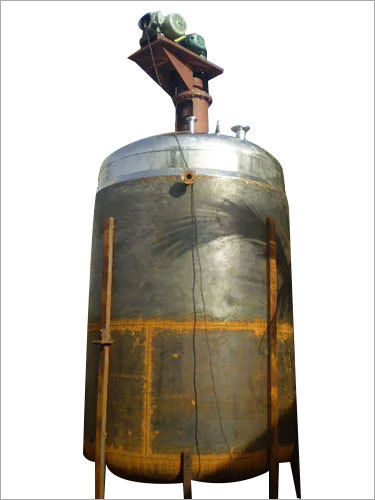

MS Pressure Filter

MS Pressure Filter Specification

- Cleaning Method

- Manual / Backwash

- Filter Type

- Pressure Filter

- Efficiency (%)

- Up to 99%

- Pressure

- Up to 16 Bar

- Capacity

- As per customer requirement

- Flow Rate

- 1000-20000 LPH (Litres Per Hour)

- Media Type

- Liquid/Solid Separation

- Connecting Type

- Flanged / Threaded

- Temperature Range

- Up to 120C

- Condition

- New

- Material

- Mild Steel (MS)

- Mesh

- Stainless Steel Mesh

- Diameter

- Customizable

- Construction

- Welded

- Medium Filter

- Liquid

- Weight

- Variable / As per design

- Shape

- Cylindrical

- Feature

- Durable, Rust Resistant, High Strength, Easy Maintenance

- Color

- Blue (Standard Industrial Finish)

- Replacement Interval

- Depends on Process & Contaminant Load

- Usage

- Industrial / Commercial / Municipal

- Application

- Water Treatment, Chemical Processing, Pharmaceuticals

- Installation Type

- Vertical / Horizontal

- Surface Finish

- Epoxy Powder Coated

- End Connection

- Flanged as per ANSI/DIN standards

- Operating Position

- Inline with Pipe Flow

- Inlet/Outlet Size

- 1 to 8 (Customizable)

- Sealing

- Neoprene / EPDM Gasket

MS Pressure Filter Trade Information

- Minimum Order Quantity

- 4 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 7 Days

About MS Pressure Filter

Supported by a team of masterly professionals and state of the art fabrication facility, we are zealously indulged in presenting the best-in-class MS Pressure Filter to innumerable valued clients. This type of filter is ideal to be used in diverse industrial sectors for meeting a variety of chemicals and fluids filtration requirement. The MS Pressure Filter is fabricated from Grade-A metal and coated with supreme class coating material to ensure its abrasion & corrosion resistance and low maintenance cost.

Robust Performance for Diverse Industries

Engineered for industrial, municipal, and commercial settings, the MS Pressure Filter handles demanding filtration tasks in water treatment, chemicals, and pharmaceuticals. With customizable diameters and flow rates ranging from 1,000 to 20,000 LPH, it delivers reliable separation of liquids and solids. The welded mild steel construction and epoxy finish provide high strength and corrosion resistance, ideal for long-term use even in harsh environments.

Flexible Installation and Maintenance Solutions

Install the MS Pressure Filter in vertical or horizontal positions to suit your piping layout. It integrates seamlessly with various operating conditions, thanks to inline connectivity and flanged or threaded end connections. Maintenance is straightforwardchoose between manual or automatic backwash cleaningfacilitating extended operational life and ease of use for operators.

FAQs of MS Pressure Filter:

Q: How is the MS Pressure Filter installed in different pipe flow configurations?

A: The MS Pressure Filter can be installed in both vertical and horizontal piping arrangements. It mounts inline with the pipe flow using flanged or threaded end connections based on ANSI/DIN standards, ensuring compatibility with a range of systems.Q: What applications can the MS Pressure Filter be used for?

A: This pressure filter is suitable for water treatment, chemical processing, and pharmaceutical sectors, as well as industrial, commercial, and municipal uses. Its design supports diverse liquid and solid separation needs across these industries.Q: When should the filter mesh or gasket be replaced?

A: The replacement interval for the mesh or gasket depends on process conditions and contaminant load. Regular inspection and maintenance are recommended to ensure optimal performance, with intervals determined by operational intensity and contaminant levels.Q: Where is this filter typically installed in a system?

A: The MS Pressure Filter is typically installed inline within the process pipeline, positioned to treat incoming liquid streams before they proceed to downstream equipment or discharge. Its shape and customizable diameter allow flexibility in placement.Q: What benefits does the epoxy powder-coated finish provide?

A: The epoxy powder coating enhances the filters durability and rust resistance, protecting the mild steel body from corrosion and extending its lifespan. This finish also helps maintain a clean industrial appearance in demanding environments.Q: How does the cleaning process work for this filter?

A: Cleaning can be performed manually by accessing and flushing out the filter element, or via backwashing to remove captured contaminants. This versatility makes maintenance straightforward and helps keep filtration efficiency high.Q: What is the maximum operating temperature and pressure for this filter?

A: The MS Pressure Filter is engineered to operate efficiently up to 120C and pressures of 16 bar, making it suitable for rigorous industrial processes requiring robust filtration solutions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

DHANANJAI EQUIPMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |